| Sharon | |||||||||||||||||||||||||||

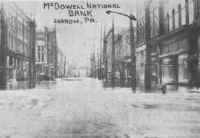

Sharon's Yesterdays & Tomorrow An Outline of the Growth of Sharon and its Industries.... and a History of the McDowell National Bank, June 1935

|

|||||||||||||||||||||||||||

|

|

Sharon's Industrial History

The Sharon District seems to be in another

period of transition. Continuous mills have made obsolete some of the old

methods of manufacturing, and the Shenango Valley is no longer the center

of production of flat-rolled steel. This center has moved to Detroit.

Water transportation has taken heavy industry to locations on water. But,

if the situation is properly dealt with, there is much to look forward to. In the two decades before 1887 the iron industry

assumed vast proportions compared with previous production, and a

beginning was made in the manufacture of rolled and finished material.

Statistics for the year 1887 are interesting for purposes of comparison.

Pig iron tonnage was 279,236; rolled iron was 47,519; there were 66,625

hundred-pound kegs of iron nails produced. Mercer County boasted of 17

blast furnaces, six rolling mills and an open-hearth steel casting plant. Through the two decades after 1887 there was an

even greater ratio of increase. In 1906 the production of pig iron in

Mercer County amounted to 1,208,294 tons. This was nearly 11 per cent of

the total produced in the State. Among the counties in Pennsylvania,

Mercer County was second in the production of pig iron, Allegheny County

being first. Steel manufacture in the Valley was limited in

1906. There were 815,913 tons produced here. This was seven per cent of

the total in the State. This county ranked third among counties. In the

same year 676,261 tons of rolled steel were produced. Mercer County ranked

second in rolled iron and steel in that year. The Sharon Steel Castings Company was organized

in 1887 and was the first steel plant in the Sharon District. Its

equipment consisted of an open hearth furnace, and the first steel seas

made there on August 26, 1887. The organizers of the company were F. H.

Buhl, Daniel Eagan and Samuel McClure. Mr. Buhl was president; Mr.

McClure, Vice president; and Mr. Eagan, secretary and general manager. The

plant was acquired by the American Steel Castings Company, which in 1902

became a constituent company of the American Steel Foundries. The Mercer

Tube plant now occupies the site. The Sharon Steel Hoop Company was organized in

1900, amid the plant was put in operation on March 15, 1901.

The original officers of the company were: Morris Bachman,

president; O.

A. Blackburn, vice president; R. A. Winterburn, secretary’; and

E. J.

Anglin, treasurer. The company originally produced billets, sheet bars,

hoops, bands and cotton ties. The Sharon Steel Works and Furnace, which was

known until recent years as the North Works of the Carnegie Steel Company,

was founded in 1896 by the Buhl Steel Company, the president of which was

F. H. Buhl. The open hearth was put into operation in May, 1897. The

blooming mill started soon after. The Buhl Steel Company was absorbed by

the National Steel Company in March, 1899, and was one of the numerous

plants of the steel corporation until dismantled in 1921 and 1922. The

blast furnace was dismantled in 1925 and 1926. Mr. Buhl was also one of the active factors in

the founding of what is now the Carnegie Steel Company plant in Farrell.

The history of what was then South Sharon began practically with the

building of the mill, which was started in February, 1900. In 1902 time

plant was taken over by the U. S. Steel Corporation. The American Sheet & Tin Plate Company and

the American Steel & Wire Company were erected to absorb the output of

the company’s local steel plants. They were built at practically the

same time as the Carnegie Mill. The period of the World War brought a great boom

to industry in the Sharon District. Following this period, in 1923, the Westinghouse

Electric and Manufacturing Company purchased the plant of the Savage

Arms Corporation in Sharpsville Avenue. The plant had been originally

the

Driggs-Seabury Corporation. The Westinghouse Company made extensive

additions and improvements to the plant. Included in its buildings is

the largest one-story building in the world. The plant is used exclusively for the production

of transformers for the Westinghouse Company. The coming of the

Westinghouse Company to Sharon was an important factor in the city’s

progress. Today the Sharon District numbers some thirty

important industries and is an ideal location for practically any kind of

new enterprise. Its present industries are: Westinghouse

Electric and Manufacturing Company, Sharon Steel Hoop Company, Carnegie

Steel Company, American Sheet and Tin Plate Company, American Steel and

Wire Company, Claire Furnace, Shenango Furnace, Sharpsville Boiler Works,

Keystone Machine Company, Pennsylvania Tank Car Company, Mercer Tube

Company. Sharon Tube Company, Petroleum Iron Works Company, Sharon

Hardware Company, National Malleable & Steel Castings Company, Air

Reduction Sales Company, Pittsburgh Steel Foundries, Standard Tank Car

Company, Sharpsville Furnace, Shenango Penn-Mould Company, Standard Slag

Company, The Tennis Company, Sharon Railway Supply Company,

Wheatland Tube Company, Valley Mould & Iron Company, Valley Cities

Brick Company, Shenango Valley Water Company, Sandow & Goldberg

Scrap Companies, P-O Electric Car Shops, and Rotter-Spear Company. |

State Street Flood 1913

Driggs-Seabury Corporation,

Sharon Steel Hoops, 1906

Related information on:

|

|||||||||||||||||||||||||